- DNOW Brands

- Flex Flow

Flex Flow

We Provide the Rental, Sale and Service of Horizontal Pump ("H-Pump") Solutions for fluid movement applications.

Flex Flow, a DNOW Company, is a leading provider of H-pump solutions for surface applications across the energy industry. We offer rental, permanent installation, and service of high-performance horizontal pumping systems (HPS) and hydraulic jet pumps (HJP) and provide our customers with the H-pump expertise they need throughout the lifecycle of their water management applications. Let our proven, reliable solutions maximize production and lower your operating costs.

The Flex Flow System: A Revolution in Fluid Movement

Discover the cutting-edge Flex Flow System that brings efficiency, flexibility and reliability to fluid movement. Our mobile Horizontal Pumping System (HPS) is engineered for rapid deployment whether for early project commissioning, enhancing operational capacity or as a timely replacement for malfunctioning equipment. Designed meticulously to match your specific flow rate and pressure needs, the system seamlessly integrates with existing control units. Plus, our state-of-the-art real-time remote monitoring ensures all safety shutdowns and alarms adhere to the highest regulatory standards.

Key Advantages:

- Optimal Fluid Transfer: Suitable for all fluid types driven by adjustable-speed electric motors.

- Versatile Pump Design: Our pumps are multistage centrifugal types primed for both high-pressure applications and low-to-medium flow transfers.

- Power Flexibility: Whether powered by your facility's electrical grid or a generator, it’s your choice.

- Economic Choice: Numerous engineers vouch for its minimal maintenance, extended run life and unmatched operating efficiency.

Our Innovative Offerings:

Horizontal Pumping System (HPS)

Flex Flow’s trailer-mounted HPS is your solution for powering single or multiple jet pumps or even SWD test pumps. Designed for mobility, it’s built to minimize maintenance needs. Its advanced filtration system ensures no contaminants compromise your operations. Choose Flex Flow for a hassle-free fluid and water transfer experience.

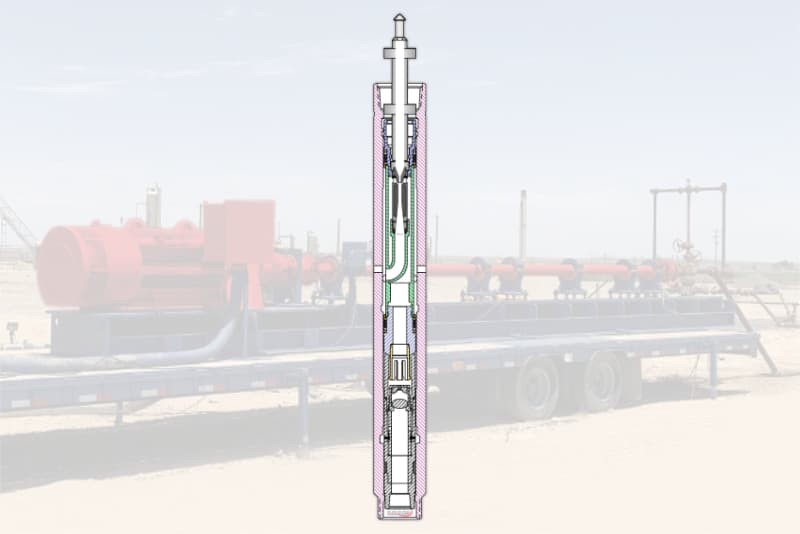

Hydraulic Jet Pump (HJP)

For challenging oilfield terrains, the Flex Flow Hydraulic Jet Pump (HJP) stands out. Efficient across vertical, deviated and horizontal wells, it boasts unparalleled gas and solid handling capabilities. Maintenance is a breeze with easy retrieval and our NODAL analysis reinforces its superiority over traditional pumps in response time and precision.

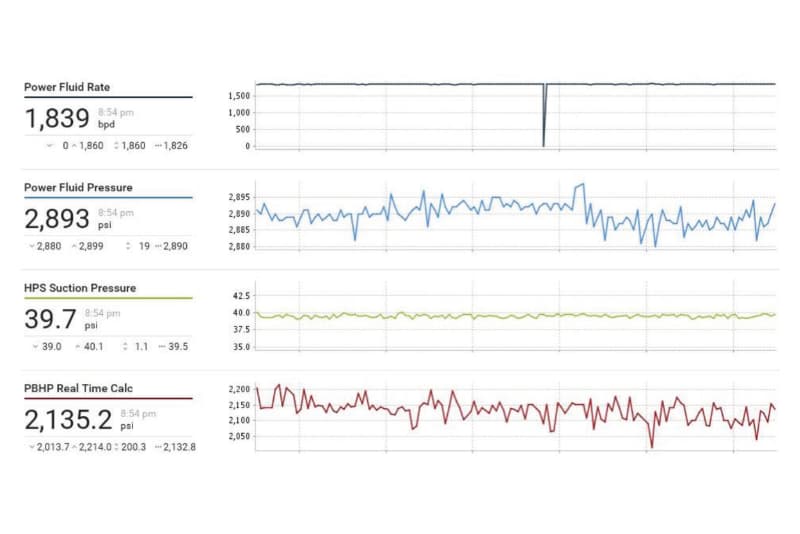

Real-time Online Monitoring

Remote monitoring of both HJP and HPS has never been this effortless. Adjust and optimize system efficiency in real-time for production, bottomhole pressure regulation or even troubleshooting. Our advanced communication options, be it digital cellular or satellite, enable the programmable logic controller (PLC) to relay updates to your preferred device from tablets to mobile phones. Stay updated with many notification choices, including emails, text messages and direct calls.

Flex Flow Solutions - Innovative. Tested. Proven.

Optimized H-Pump Solutions for Completion, Production and Water Management

Flex Flow Services leverages advanced technology to enhance efficiency and minimize risk across completion, production and water management operations. Our Horizontal Pumping System (HPS) is adept at optimizing an array of operations from water supply and injection to artificial lift, disposal and distribution. Whether you require a mobile, trailer-mounted setup or a permanent fixture, the HPS guarantees optimal fluid transfer with automated reporting capabilities.

HPS salt water disposal (SWD) solution

A cohesive system, the HPS SWD melds the horizontal pumping setup with variable speed drives, surface controls and automated reporting. This integration aims to reduce the operational cost tied to saltwater disposal.Pitted against conventional triplex positive displacement pumps, the HPS emerges superior in cost and performance regardless of the choice between trailer-mounted or permanent installations.

With field-proven multistage centrifugal pumps, the HPS is tailored for high-pressure, medium-to-low flow saltwater transfer.

Engineers acclaim its lower maintenance costs, extended run life and unmatched operational flexibility.

Flexible rental solutions are available for short-term needs as well as purchase options for long-term commitments.

HPS water and fluid transfer solution

Our water and fluid transfer solution deploy a unique trailer-mounted or permanent horizontal pumping system that can be used to transfer water in a variety of production operations. The highly mobile HPS solution requires little maintenance, so service callouts are kept to a minimum. In addition, it has a robust filtration system that prevents impurities from entering the pump or the wellbore.

Ideal for all fluid transfer operations, the HPS system is engineered to match flow rate and pressure requirements. It is equipped with real-time remote monitoring to support safety shutdowns/alarms according to all regulatory requirements when connected to existing control systems.

Hydraulic jet pump (HJP) artificial lift solution

We offer operators artificial lift solutions from flow back through production with a unique horizontal pumping system (HPS) and versatile hydraulic jet pumps (HJP) that provide advantages over rod lift and ESP systems in many environments.

Our goal is to lift higher volumes and reduce operating costs by eliminating the common issues of artificial lift gas locking and solids handling, maintaining production over a wide range of rates and reducing well intervention and maintenance downtime.

For artificial lift operations, our solution combines a unique horizontal pumping system (HPS) with a versatile hydraulic jet pump (HJP) to provide many advantages over conventional artificial lift systems:

- Lower operating costs leading to reduced LOE

- Less maintenance with minimal downtime (98% to 100% run time)

- Highly mobile with a unique trailer-mounted system

- An efficient filtration system that prevents impurities from entering the pump and wellbore.

- Usage of a versatile downhole jet pump in conjunction with a gas lift and many completion scenarios (conventional, reverse circulation, and concentric).

Additional Applications

- Enhanced oil recovery (EOR) systems

- Gathering systems

- Production and separation systems

- Steam-generating plants/distribution systems

- Storage systems

- Crude oil and NGL boosting and transfer

- Process fluids transfer

Benefits

- Rapid response from the trailer-mounted system

- Lease-to-own or staged purchase options requiring zero CAPEX

- Proven reliability (98% - 100% run time) with 24/7 support

- Automated reporting and monitoring

- Cost-effective rental options for temporary installs to provide testing for permanent equipment or to replace equipment under repair

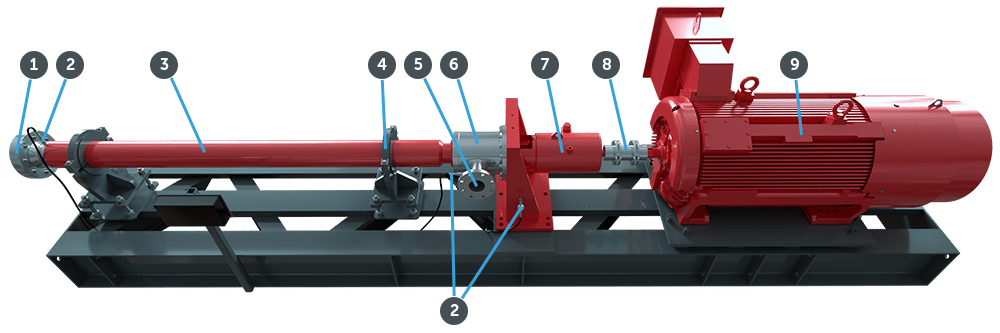

Engineered Reliability Solutions for Horizontal Pumping Systems

Straight from our pump experts at Flex Flow, Flex-Fit is a comprehensive program designed to get to the root cause of your horizontal pumping system (HPS) issues. Flex-Fit is an engineered solution that increases mean time between failures and improves overall system efficiency. Here's what Flex-Fit offers:

- Component calibration, alignment, optimization, sizing, repair, replacement, retrofits, substitutions and upgrades

- Analysis of failures, distortion, vibration, nozzle loading, piping connections and overall efficiency

- Expert advice, best practices and valve selection

Flex-Fit Focuses on Key Pump Components

Our experts have identified 9 key components as common failure points for horizontal pumping systems. The Flex-Fit program targets these components with options to monitor, adjust, repair, replace or upgrade, based on your specific applications and needs.

| 1 | Discharge heads, flow meters, valves |

| 2 | Instrumentation transducers |

| 3 | Pump barrels |

| 4 | Saddles |

| 5 | Intake |

| 6 | Mechanical seal |

| 7 | Thrust chamber |

| 8 | Motor coupling |

| 9 | Motor |

Ready to get started with Flex-Fit?

Click the button below and submit an equipment survey today. The Flex Flow team will contact you directly to start optimizing your HPS and lowering your operating costs.

Real-Time Monitoring and Optimization for Horizontal Pumping Systems

Get the most from your pumps with OptiWatch high-quality hybrid pump system monitoring from the pump experts at Flex Flow. OptiWatch offers detailed system monitoring capabilities with real-time response and asset lifecycle management tools that help you focus on your operations, minimize equipment problems and maximize profits.

OptiWatch Capabilities

- Dashboard of overall system health and status

- Equipment inventory tracking

- Advanced trend mapping across a range of parameters

- Carbon footprint and power cost analysis

- Interpretative algorithms

- Self-plotting pump curves

- Maintenance program scheduling

- Daily pump status and reports

Ready to get started with OptiWatch?

Click the button below and complete the contact form. The Flex Flow team will reach out to you directly to start monitoring your pumping systems and maximizing your profits.

The Flex Flow System has a successful track record

2018 case study shows how the Flex Flow System can add to the bottom line

Opportunity

An operator in Andrews, Texas, wanted a high-flow solution that would maximize well profitability.

Well specifications

- Casing 5 1/2 inches

- Tubing 2 7/8 inches

- TVD 6,680 ft

Equipment specifications

- Free-style standard-flow jet pump with an E:11 throat and nozzle

- 300-hp surface pumping unit

Success

The Flex Flow system, comprising a horizontal pumping system (HPS) and a hydraulic jet pump (HJP), proved to be a highly profitable artificial lift method. The incremental lifting cost was $24,000 or $11/bbl per month. With a net oil price of $45 and total monthly production of 2,088 bbl, the incremental monthly operating cash flow was $70,992.

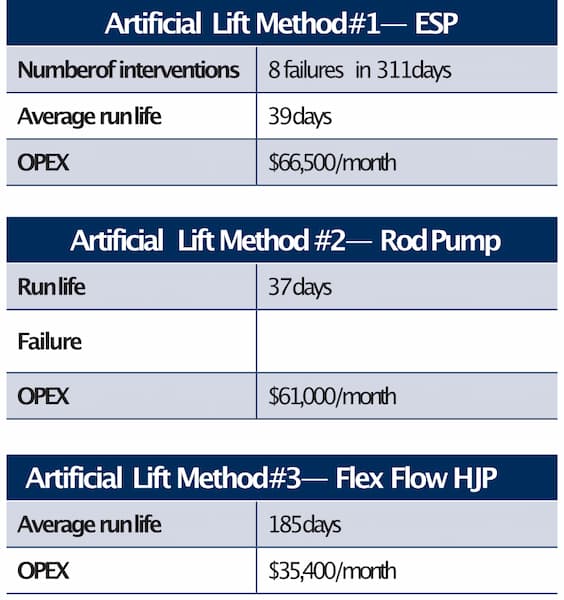

2018 case study shows how the Flex Flow System can reduce OPEX/Interventions

Opportunity

In Andrews, Texas, an operator was plagued by high sand cut (1% to 3%), which caused a high failure rate in a well completed with an electrical submersible pump (ESP). The well was reconfigured to rod lift but failed 37 days after wearing out 115 tubing joints. The Flex Flow system was installed to reduce OPEX and the frequency of interventions.

Well specifications

- Casing 5 1/2 inches

- Tubing 2 7/8 inches

- TVD 9,500 ft

Success

The Flex Flow horizontal pumping system (HPS) and hydraulic jet pump (HJP) extended run life from ~38 days to 185 days, reducing OPEX/month by more than $25,000. Eliminating six interventions per year saved hundreds of thousands of dollars.

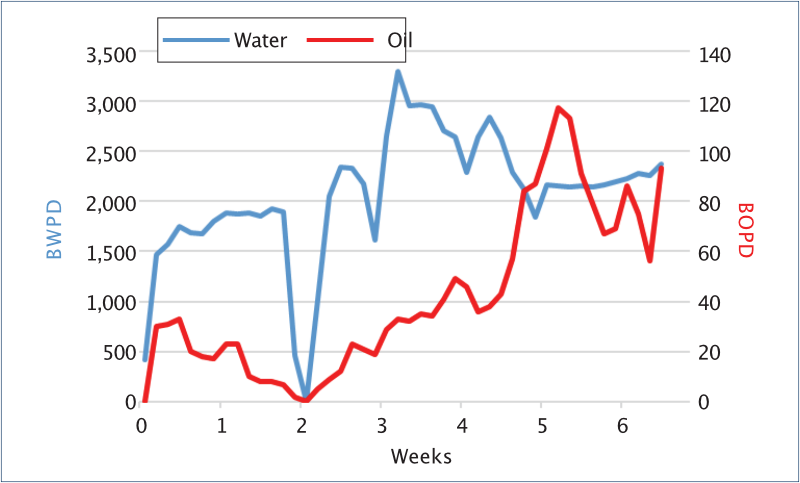

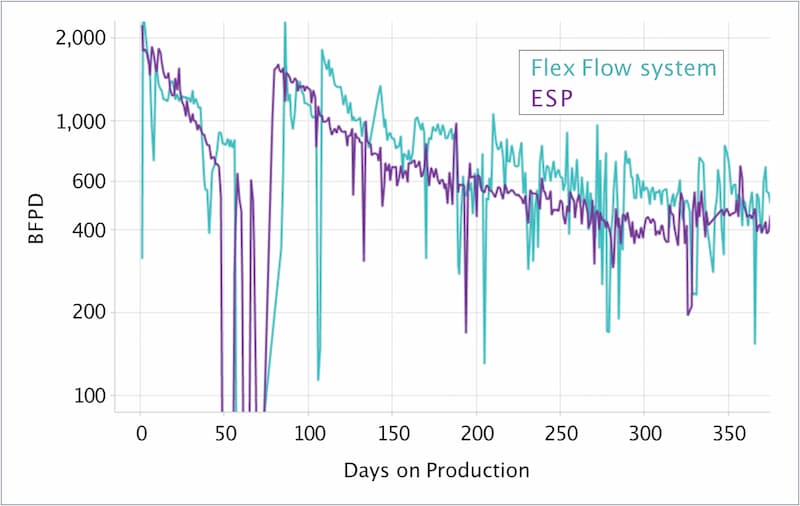

2018 case study shows how the Flex Flow System can achieve faster Frac flowback

Opportunity

An operator in Andrews, Texas, allowed Flex Flow to compare the performance of an electrical submersible pump (ESP) with a Flex Flow system comprising a horizontal pumping system (HPS) and a hydraulic jet pump (HJP). The test was run in two adjacent and similar wells after hydraulic fracturing and flowback. Well 1 was lifted with a Flex Flow system, and Well 2 was placed on an ESP.

Well specifications

- Casing 5 1/2 inches

- Tubing 2 7/8 inches

- TVD 10,000 ft

Success

The Flex Flow system consistently lifted higher volumes than the ESP during the first year of production. In addition, the Flex Flow system has a lower upfront cost than the ESP, making it the best choice for dewatering the well.

Flex Flow locations

If you are in need of completion, production and water management technology to lower operational risk and improve operational efficiency, our locations across the country can help you. Visit one of our locations, or contact us for more information. Trust the experts at our to help you find the right h-pump solution for your surface applications needs.

Type:

Type:

Type: