- Industries

- Mining and Minerals

Mining Industry Solutions

Durable, High-Performance Products & Industrial Support

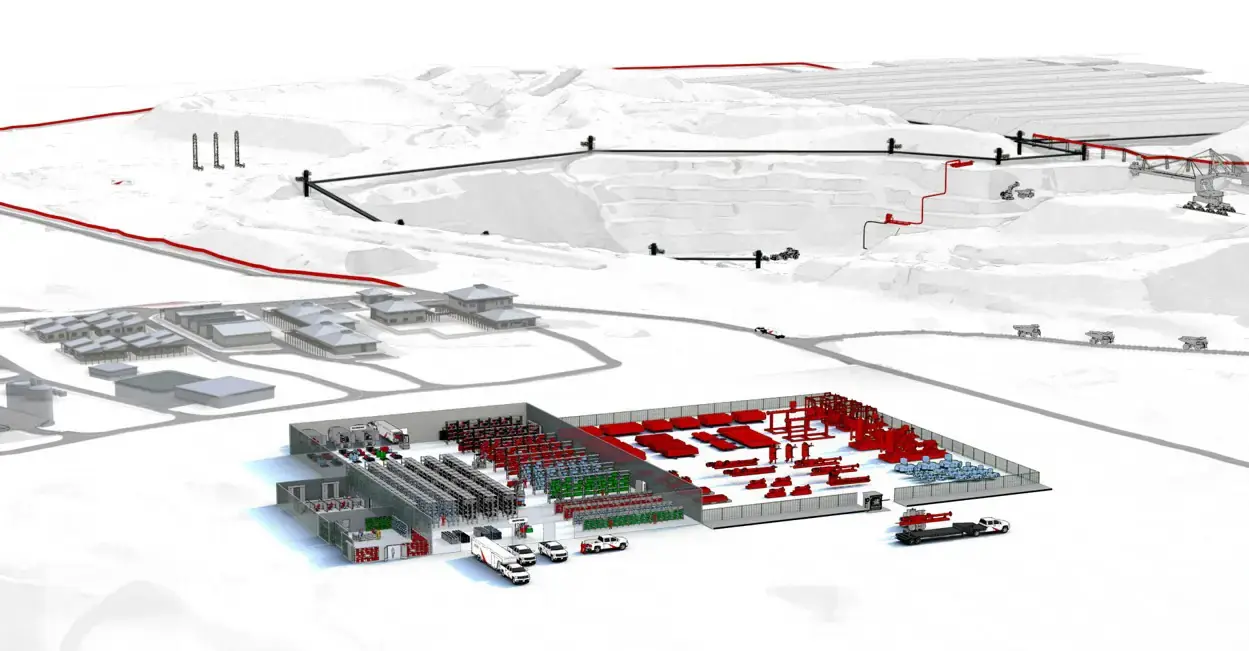

DNOW is your trusted supplier of PVF, industrial supplies, engineered equipment and end-to-end support for mining operations across multiple mining sectors and regions. Whether you’re extracting soda ash in Wyoming, gold in the Rockies, lithium from Nevada brine, copper in Pinto Valley or operating across the Pilbara region of Australia, DNOW delivers the products, services and technical expertise to keep your operation running efficiently and safely – on time and on budget.

Backed by our specialized affiliated brands such as Odessa Pumps, Power Service, Flex Flow and MacLean International, DNOW helps you streamline operations and minimize downtime across every phase of your mining operation, from exploration and development to extraction, processing, tailings management and reclamation.

What DNOW Offers the Mining Industry

Mining operations demand durability, performance and operational resilience. DNOW supplies the heavy-duty products and industrial infrastructure needed to meet those challenges in extreme environments.

Featured Mining Technologies (Territory-Specific)

Specialty Valves for Critical Mining Processes

DNOW offers severe-service isolation and control valves engineered for abrasive slurry, corrosive brine and acid-leach circuits.

Our Green River, WY Process Solutions branch stocks the broadest valve inventory; specialty ranges are also supported through select DNOW locations in CO, MT and ND. Outside those regions we supply equivalent solutions through our national distribution network—contact us for the best fit.

Mechanical Seals & Flush-Pan Solutions

- API- and MSHA-compliant mechanical seals for slurry pumps, vertical turbine pumps and multistage transfer pumps, configured for high-solids and high-temperature duty cycles

- Mining-specific seal families such as SLC-style slurry seals, SLM medium-duty seals and compact cartridge seals for tight equipment envelopes

- Custom flush-plan design (API 682 Plan 11, 32, 54 and water-saving Plan 31 equivalents) to extend mean time between replacements (MTBR) and reduce water usage

- In-house seal expertise concentrated in Wyoming, Colorado, Montana and North Dakota, with all major seal brands supported nationwide through DNOW Pump & Seal Centers of Excellence

Mining Sectors & Applications We Serve

DNOW supports a wide range of mining operations with tailored product packages, technical services and logistics expertise. From the world’s largest trona deposits in Wyoming to lithium brine fields in Nevada and rare-earth extraction in Australia, DNOW is your trusted industrial supply partner across every major mineral sector. Explore how we support each mining application with proven solutions designed for safety, efficiency and uptime.

Key Products

- Corrosion-Resistant Piping Systems – Soda ash mining involves harsh chemical environments, particularly during trona ore processing, where hot water injection and brine filtration are critical. DNOW supplies high-nickel alloy and composite pipe engineered to withstand corrosive fluids and high-pressure conditions. These materials are essential for solution mining, where trona ore is dissolved into brine and transported to processing facilities.

- Filtration & Fluid Handling Equipment – The filtration of trona brine to remove particles as small as 25 microns is a key step in soda ash production. DNOW provides mechanical filtration systems, abrasion-resistant valves and slurry pumps designed for high-solids content. Our partnerships with top manufacturers ensure compatibility with stainless steel (AISI 304L/316L) components, maintaining fluid purity and system longevity. Our slurry pumps also support high-efficiency dewatering and processed materials transport.

- Modular Processing Units – To streamline onsite operations, DNOW offers pre-engineered equipment packages for mineral processing plants. These modular skids integrate pumps, valves and control systems tailored for trona refining, reducing the need for custom fabrication. For example, our systems support the conversion of trona brine into dense soda ash (Na₂CO₃) through crystallization processes, which require precise temperature and pH control.

Processes Supported: milling, CIP/CIL cyanide leaching, refining

Key Products

- Specialized Mining Equipment & Supplies – DNOW supplies cyanide-resistant pipe, valves, fittings and flanges and dosing pumps engineered to withstand aggressive chemicals. These components are particularly crucial in gold and silver mining operations like the Witwatersrand Basin, where underground mining conditions include corrosive, high-dust, high-temperature, low-visibility and moisture-prone environments.

- Processing & Production Equipment – Efficient mineral recovery depends on precision control over the crushing, grinding and extracting of precious metals from ore. DNOW offers a range of pumping solutions, measurement devices and modular processing equipment that support continuous, optimized operations. Our systems are tailored to gold and silver extraction needs, with a focus on maximizing metal recovery and minimizing operational downtime.

- Pumps, Production & Drilling – Silver is frequently extracted as a byproduct of gold, copper, lead and zinc minin, requiring complex fluid handling systems that can process mixed-material flows. DNOW delivers fluid handling solutions and production equipment to meet this complexity, including chemical dosing, slurry transfer and dewatering systems suited for variable mining conditions.

- Safety Equipment & Compliance Solutions – Safety remains paramount in mining operations, particularly in underground environments where confined spaces and hazardous gases are prevalent. DNOW provides elite safety equipment, gas detection systems and MSHA-compliant PPE, along with services for rental, inspection and repair. Our comprehensive approach to safety compliance helps mining operations meet regulatory standards while protecting their workforce.

Methods Supported: brine and hard rock (spodumene) extraction

Key Products

- Pipe, Valves & Fittings (PVF) for Processing Systems – Lithium extraction, whether from brine pools or spodumene ore, involves corrosive chemicals and complex processing steps. DNOW provides robust piping infrastructure designed to withstand extreme operating environments:

- Carbon steel pipe for industrial strength and durability

- Stainless steel and alloy piping for high corrosion resistance

- Fiberglass and composite pipe for specialized chemical applications

- Comprehensive valve and fitting selections compatible with diverse processing requirements

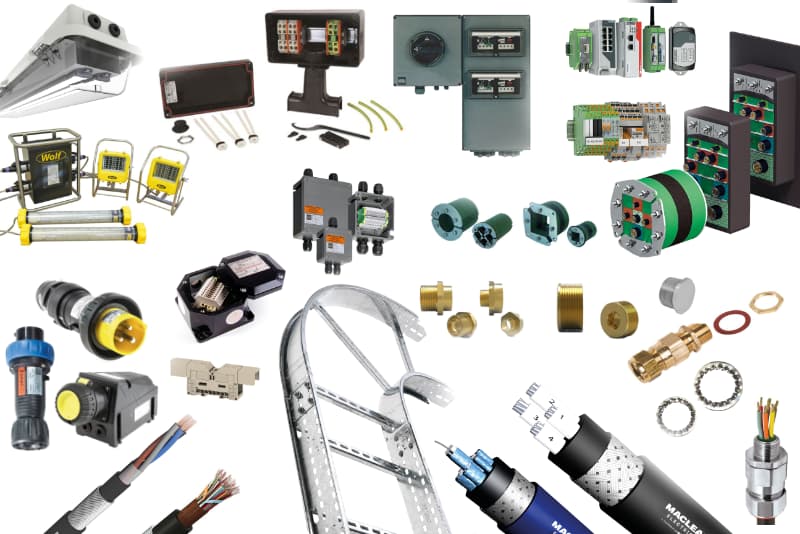

- Electrical Equipment & Power Solutions – Lithium mining operations – particularly those pursuing sustainable extraction methods such as all-electric mining initiatives – require specialized electrical infrastructure. DNOW offers:

- Industrial batteries and charging solutions for heavy-duty machinery applications

- Electrical cables and products designed for industrial environments

- Power distribution equipment suitable for mining applications

- Safety Equipment & Environmental Compliance Solutions – Safety and compliance are critical in underground and surface lithium mines. DNOW provides:

- Personal protective equipment (PPE) for hazardous chemical handling

- Safety services including inspection, maintenance and compliance support

- Environmental monitoring equipment to maintain regulatory compliance

- Material Handling & Processing Equipment – The extraction and processing of lithium requires specialized equipment that DNOW can supply:

- Brine-compatible pumping solutions, dosing systems and high-pressure pumps

- Process and production equipment for refining and purification stages

- Material handling systems, mill supplies and MRO consumables for daily site operations

Processes Supported: crushing, grinding, flotation, SX/EW, smelting

Key Products

- Pipe, Valves, Fittings & Flanges – Copper mining operations require reliable fluid handling systems across multiple stages, including slurry transport, heap leaching and solvent extraction (SX/EW). DNOW provides:

- Slurry valves and abrasion-resistant pipe for tailings and concentrate handling

- Rigid and flexible copper tubing for specialized flow systems

- Full range of carbon steel, stainless steel and alloy fittings and flanges

- Industrial Fittings & Connectors – DNOW's high-performance fittings deliver durability in corrosive, high-pressure mining environments. Our carbon steel and alloy connectors are engineered to extend equipment life, reduce maintenance intervals and improve overall system reliability, a necessity in abrasive slurry circuits and acid leach fields.

- Specialized Mining Equipment & Supplies – DNOW supports surface and underground copper mining with a broad inventory of field-tested industrial products. From flotation and dewatering systems to SX/EW components and refining infrastructure, our equipment is built to hand dust-intensive, corrosive and high-temperature conditions.

Applications Supported: sulfide mining, laterite mining, cobalt refining

Key Products

- Critical Infrastructure Components – Nickel and cobalt mining operations rely on robust systems that can withstand highly acidic and corrosive environments, particularly in hydrometallurgical plants used for metal separation and refining. DNOW supplies:

- Acid-resistant valves, lined piping and tank hardware

- Electrical cable, instrumentation and power distribution systems

- Full range of PVF products, including carbon steel, stainless steel and alloy components

- Production & Processing Equipment – The nickel and cobalt beneficiation process involves multiple stages – crushing, grinding, flotation and leaching – with each requiring durable and efficient equipment. DNOW provides:

- Pumps, agitators and dosing systems for slurry and chemical handling

- Tank components and mixing systems used in solvent extraction and crystallization

- Solvent extraction packages engineered for recovery and purification

- Tools, MRO & Operational Support – DNOW also supports daily mining operations with a full line of mill supplies, tools, industrial lubricants and MRO consumables. These essentials help reduce downtime, ensure safety and maintain consistent productivity across mining sites and refining plants.

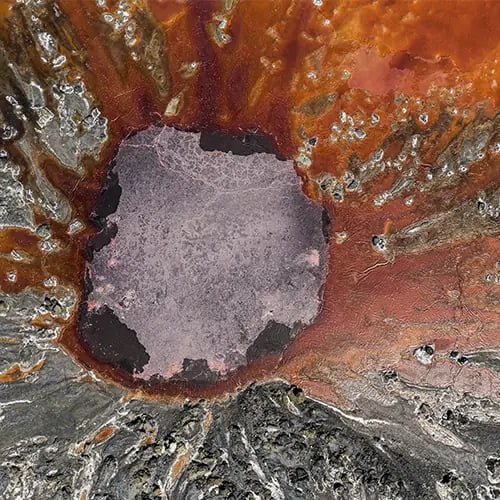

Applications Supported: open-pit mining, solvent extraction, acid mine drainage

Key Products

- Pipe, Valves, Fittings & Flanges – Fluid handling in rare earth element processing often involves high-acidity environments, particularly during the acid leaching and solvent extraction (SX) phases. DNOW supplies:

- Acid-resistant piping systems (lined, alloy and composite)

- Valves and fittings designed for chemical compatibility

- Tailing transport systems engineered to handle abrasive and corrosive slurries

- Pumps, Production Equipment & Drilling Products – Rare earth element mining sites require precise and durable pumping solutions, especially for SX circuits, brine processing and waste handling. DNOW offers:

- Chemical dosing systems, centrifugal pumps and diaphragm pumps

- Drilling support products for exploration and development

- Modular skids designed for remote and custom-engineered REE applications

- Mill Supplies, Tools, MRO & Consumables – To maintain uptime and ensure consistent operations, DNOW provides a full suite of MRO essentials:

- Tools, lubricants and industrial supplies

- Consumables for day-to-day facility maintenance

- Equipment to support material handling and light fabrication

- Electrical Cable & Products – Powering REE mining operations, often located in remote or off-grid areas, requires resilient electrical infrastructure. DNOW supports these needs with:

- Mining-grade electrical cable, bulk wiring and connectors

- Power distribution and automation panels

- Explosion-proof and corrosion-resistant electrical enclosures for SX and leach circuits

Applications Supported: underground (longwall, room and pillar) and surface operations

Key Products

- Pipe, Valves & Fittings (PVF) – Coal mining operations require durable and pressure-rated components to support fluid transport, process water systems and chemical transfer. DNOW offers:

- Pipe, valves, fittings, flanges and gaskets for high-demand environments

- Fasteners and supports to maintain system integrity in underground and surface operations

- Pumping Solutions – Dewatering and slurry control are critical for maintaining productivity and safety. DNOW supplies:

- Mine-rated dewatering pumps, slurry pumps and chemical transfer systems

- Pump skids designed for underground mobility and remote operation

- Electrical & Instrumentation – Power and control systems in coal mines must withstand harsh, dusty and potentially explosive environments. DNOW provides:

- Mine-rated cable, electrical panels and conduit systems

- Instrumentation and measurement devices for flow, pressure and system monitoring

- Explosion-proof equipment certified for underground mining applications

- Modular Process Equipment – DNOW offers modular process and production equipment designed to support coal separation, crushing, screening and material handling. These systems are engineered for space-constrained sites and fast deployment in field conditions.

- Safety Products & PPE – Worker safety is paramount in coal mining, particularly in underground settings. DNOW delivers:

- Personal protective equipment (PPE) for dust, gas and confined space exposure

- Gas detection, ventilation support and emergency response gear

- Safety services such as inspection, maintenance and training packages

- Mining-Specific Products & Materials – To support daily maintenance and reduce downtime, DNOW offers:

- Tools and industrial supplies

- Lubricants, fasteners and industrial consumables tailored for rugged environments

Processes Supported: Fertilizer production, tailings management

Key Products

- Pipe, valves, fittings and flanges engineered to resist corrosion from potash and phosphate materials, especially during solution mining and brine circulation. DNOW provides:

- Corrosion-resistant PVF systems engineered for chemical compatibility

- Materials suitable for handling heated brine, phosphate slurry and tailings

- Gaskets, fasteners and specialty flow components for mining and processing plants

- Pumping solutions critical for underground conventional mining and solution mining applications. DNOW offers:

- Brine-compatible pumps, chemical dosing systems and slurry transfer units

- Skid-mounted and mobile systems suitable for remote mining sites

- Tailing management pumps designed for continuous operation

- Electrical components and instrumentation systems to monitor and control complex mining processes. DNOW supplies:

- Electrical distribution systems, bulk cable and mining-rated wiring

- Instrumentation systems for flow control, pressure regulation and process automation

- Solutions for plant SCADA systems, ensuring data-driven performance optimization

- Processing Equipment Support - The processing of potash and phosphate ore involves multiple specialized steps, including size reduction, desliming, separation, drying and compaction. DNOW supports these critical processes by offering:

- Components for phosphate beneficiation systems, including scrubbing, attrition, cyclone and dewatering equipment needed to process phosphate ore

- Materials for potash processing facilities handling challenging processes like sylvite extraction and carnallite precipitation

- Maintenance, repair and operating (MRO) supplies essential for continuous operations in these facilities

Processes Supported: Quarrying, processing, logistics

Key Products

- Pumps & Fluid Management Solutions – DNOW's U.S. Process Solutions group provides a wide range of pumping products crucial for aggregate mining operations. Their offerings include:

- Centrifugal pumps, positive displacement pumps and various surface pumps designed to handle the rigorous demands of mining environments

- Solutions for dewatering, material slurry transport and process water circulation

- Skid-mounted and customizable units for portable or fixed site applications

- Pipe, Valves, Fittings (PVF) & Infrastructure Products – DNOW supplies robust PVF systems essential for water management and material handling in aggregate mining. DNOW offers:

- Abrasion-resistant pipe, valves, fittings and flanges

- Products designed to perform in dusty, high-impact environments

- Infrastructure components for wash plants, processing stations and transport systems

- Tools, Equipment & Maintenance Supplies – DNOW helps aggregate mining operations minimize downtime with a comprehensive inventory of essential products:

- Hand tools, power tools, air tools and cutting tools

- Maintenance equipment such as annular cutters, broaches, burrs and chamfering tools

- Process Solutions & Specialized Equipment – DNOW delivers customized equipment packages built for quarry and aggregate sites, backed by decades of industry experience. Our process solutions are optimized for a variety of applications:

- Corrosive and dust-intensive environments

- Crushing, screening, washing and classification stages

- Integration with site-specific flow and logistics needs

- Supply Chain Management Solutions – DNOW supports aggregate producers with proprietary materials management and integrated supply chain solutions, including:

- Inventory visibility and demand forecasting

- Optimized procurement for remote or high-volume sites

- Custom workflows to reduce lead times and improve uptime

Additional Support & Supply Chain Services

DNOW offers a comprehensive suite of services to boost efficiency, reduce downtime and optimize procurement for any type of mining operation.

Key Service Areas

- Technical Expertise & Engineering Support

- Specialized knowledge for complex extraction processes (e.g. - cobalt, lithium, rare earth elements)

- Engineering support for system design, corrosion-resistant materials and custom solutions

- 24/7 technical assistance to minimize downtime

- Digital Technology Integration (DigitalNOW®)

- eCommerce and data management tools

- Remote monitoring and digital workflow management

- Streamlined procurement and inventory processes

- Operations & Supply Chain Management

- Supercenter distribution network for rapid logistics, even in remote areas

- Inventory, warehouse and procurement solutions

- Customized operations for rare-earth and critical mineral mining

- Regionalized distribution model to enhance efficiency and reduce costs

Field & Shop Service Capabilities

- 24/7 on-site service for pumps, valves, mechanical seals, air compressors and associated rotating equipment, covering inspection, laser alignment, vibration analysis and emergency repair

- OEM-trained technicians deployed from strategically located Process Solutions shops, with rapid mobilization to remote mine sites across North America and Australia

- Pump and seal shake facility in Billings, Montana featuring a state-of-the-art test stand capable of up to 5,000 GPM and 500 HP for performance verification, dynamic balancing and seal qualification

- Valve automation and repair that includes torque testing, actuator retrofits and hydrostatic pressure testing to ANSI and API standards

- Comprehensive parts management via DigitalNOW® for real-time inventory, repair history and predictive-maintenance scheduling

Specialized Mining Solutions

Beyond product delivery, DNOW adds value through application-specific expertise, vendor-aligned packages and responsive support. Our affiliated brands – Odessa Pumps, Power Service, Flex Flow and MacLean International – offer unique capabilities in pump rental, engineered systems, hazardous area electrical solutions and real-time equipment monitoring. These solutions are field-tested and aligned with the evolving needs of modern mining operations.

Pump Rentals & Field Support

Through Odessa Pumps and Power Service, we offer self-priming, centrifugal, vacuum-assist and electric diaphragm pumps, plus full-service repair and 24/7 field support. We help you stay operational through floods, shutdowns or urgent needs.

MacLean International Expertise

As a DNOW company, MacLean provides hazardous-area electrical and cabling solutions, corrosion-resistant enclosures and support for both surface and underground mining – especially in Australia, the UK and Africa.

Flex Flow Fluid Management

Flex Flow offers real-time pump monitoring and high-pressure systems (up to 6,000 PSI), ideal for mine dewatering, slurry transport and hydraulic jet pumping in remote or rugged locations.

Why DNOW is the Supplier of Choice

For mining companies across North America and Australia, DNOW stands out for its unmatched service, technical knowledge and regional reach. Our broad inventory, digital procurement tools and industry-leading partnerships allow us to serve both remote and high-volume operations with speed and reliability. We go beyond supply: we offer solutions that solve real problems on the ground.

Proven Mining Experience

Hundreds of mining customers across North America and Australia rely on DNOW for mission-critical products and services.

International Reach, Local Support

With strategically located facilities, DNOW delivers responsive service with in-region inventory and engineering support.

Commitment to Safety

DNOW helps meet MSHA, OSHA, EPA and local compliance standards while supporting your carbon reduction goals.

Focus on Critical Minerals

We actively support the mining of essential inputs for the energy and defense industries, including lithium, cobalt and rare earth elements.

Partner With DNOW

From exploration to extraction, refining to reclamation, DNOW is your reliable partner for mining supplies, custom solutions and operational support.

Contact us to request a quote or consult with a DNOW mining specialist and Run Stronger today.