- DNOW Brands

- Flex Flow

- Hydraulic Jet Pump

Hydraulic Jet Pump (HJP) Solutions

Flex Flow's hydraulic jet pump is a top-tier solution designed to boost artificial lift well operations and enhance profitability. This jet pump stands out in the oil and gas sector, offering adaptability for vertical, deviated and horizontal wells. With an impressive flow rate of up to 100,000 BF/D, it’s a go-to choice for professionals seeking efficiency in gas and solids management. Its easy retrieval feature cements its position as a leader in jet pump lifting systems.

Product Information

Product Highlights

- Operates seamlessly in various well types

- Onsite maintenance without the need for a workover rig

- Advanced solids handling with no downhole moving parts

- Versatile production rates ideal for frac flow backs

- Perfect for multi well pads and deviated wells

- Enables the deployment of corrosion inhibitors and well bore chemicals

- Skilled in managing sand and solids production

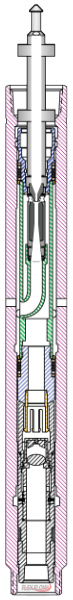

How the Hydraulic Jet Pump (HJP) Works

At the heart of the HJP are its nozzle, throat and diffuser. Fluid is directed into the nozzle at high speeds, generating a pressure difference. This kinetic energy, produced as fluid exits the nozzle, aids in drawing more fluid into the diffuser, converting it to a high-pressure state. Given these capabilities, Flex Flow's jet pump is a preferable choice in challenging oilfield scenarios over traditional lift systems.

Hydraulic Jet Pump

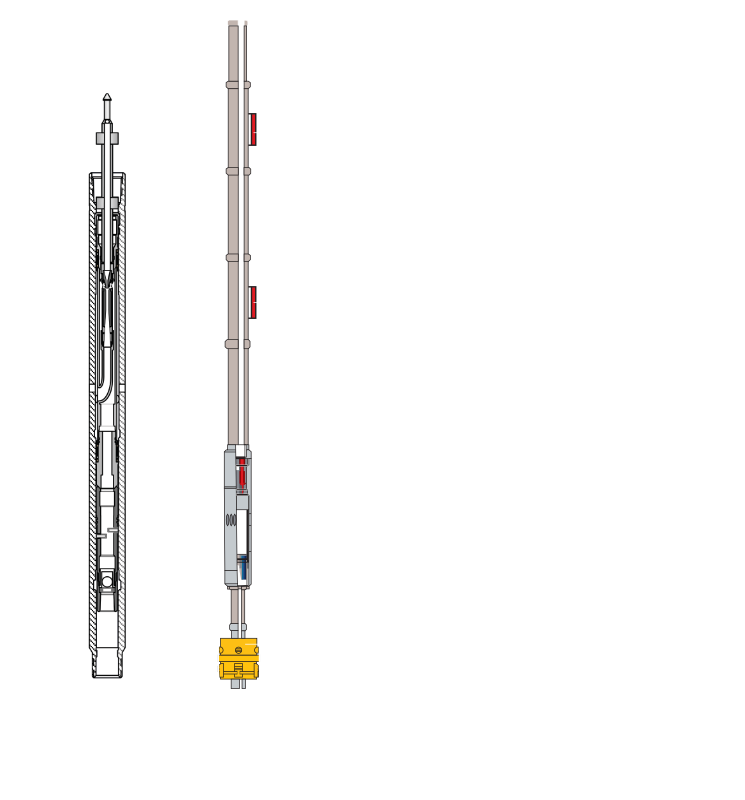

Select Component Breakdown

Key components of this hydraulic jet pump include:

- Bottom hole assembly (BHA)

- Housing J-Tube

- Standing valve

- Carrier

Depending on the depth, the expected downtime is +/- 1 hr for intervention.

The jet pump is deployed by connecting it to the BHA and dropping it down the hole. The housing and carrier will sit at the bottom with metal-to-metal contact. If you need to retrieve the carrier, you can do so by reversing flow rates to the annulus.

This will enable the carrier to pass through the tubing string and be isolated by shutting the master valve. After any inspection or replacement of throats and nozzles, the carrier can be dropped from the surface and production will resume.

BHA

Housing

J-Tube

Standing Valve

Carrier

Required Surface Equipment

- A horizontal pumping system is used to provide needed power fluid to the jet pump nozzle to create the venturi effect.

- Holding tanks for power fluid. Additional tanks can be used to set for well production as an independent battery.

- Three-phase separator separates power fluid from the produced fluid, allowing production to be sent to central battery.

Operator Benefits

With Flex Flow's hydraulic jet pump, operators enjoy a slew of advantages. No sliding sleeves needed, zero seal leakage and eliminating interventions during gas lift valve installations are just a few to mention. There are eight steps needed to implement this cost-saving solution:

- The gas lift mandrels and hydraulic jet pump (HJP) bottomhole assembly (BHA) are run in the hole above a packer.

- The well is allowed to flow back naturally until loaded up. (An isolation sleeve can be installed in the BHA if required.)

- The isolation sleeve is removed via wireline when the well loads up.

- The standing valve and HJP are pumped into the well.

- Jet pump operations begin, and solids are unloaded and cleaned up until the gas/liquid ratio increases.

- The HJP and standing valve are retrieved via wireline.

- The isolation sleeve is set in the BHA via wireline.

- Gas lift operations are started up.

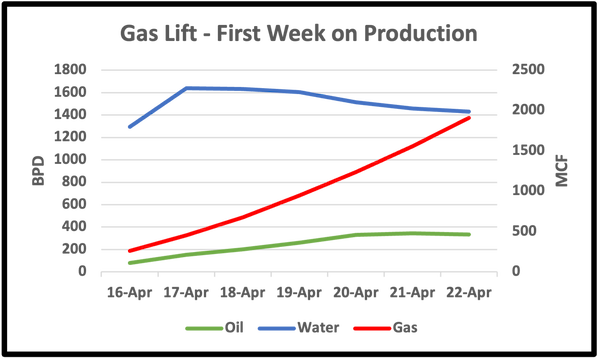

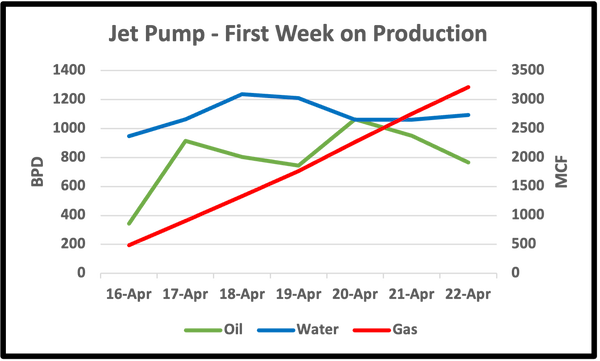

HJP design outperforms gas lift in a head-to-head

Opportunity

A customer in the Permian Basin completed a 4-well pad in hopes of putting all wells on a gas lift. Due to insufficient amounts of make up gas to power their surface infrastructure, a jet pump/GL hybrid design was deployed in one well to allow all wells to produce in the interim. Once all wells produced enough gas, the HJP would be pulled, and gas lift operations would commence.

Success

The HJP system continued to outperform the offset GL wells in terms of overall oil production, contributing significant gas volumes to the customer’s GL surface facilities. The HJP well sustained significant oil production throughout the early stages of production before eventually being proactively pulled to allow GL operations to proceed.

About Flex Flow

Flex Flow, a DNOW Company, is a trailblazer in delivering H-pump solutions for surface applications in the energy landscape. We pride ourselves on our expertise in hydraulic jet pumps and horizontal pumping systems (HPS), guiding our clients through their water management ventures.