- Products & Services

- Pumps

- Positive Displacement Pumps

- Progressive Cavity Pumps

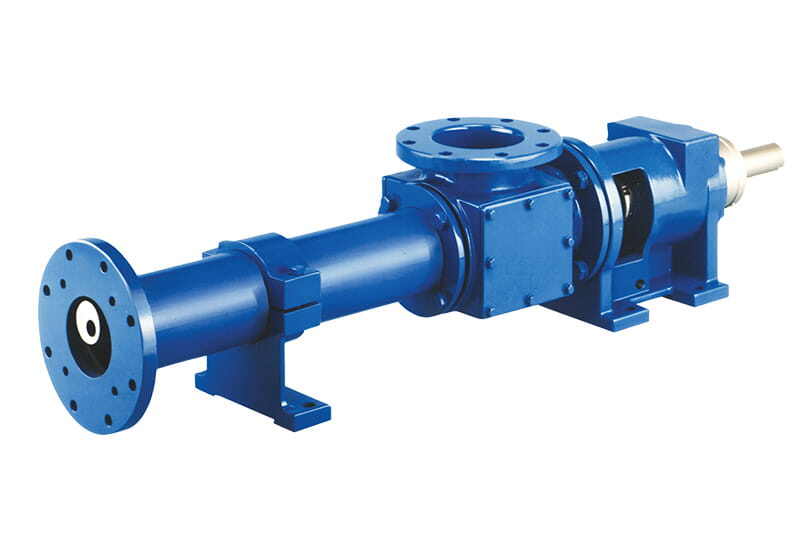

Progressive Cavity (PC) Pumps

Revolutionizing Fluid Transfer in Oil and Gas: Precision Engineering for High-Viscosity Challenges

In the modern oil and gas sector, efficiently handling high-viscosity and shear-sensitive liquids is crucial. Our affiliated brands Odessa Pumps and Power Service proudly present our elite progressive cavity (PC) pumps. Crafted to tackle the distinct challenges of fluid metering and viscous material pumping, our pumps are more than just machines; they're the answer to the contemporary challenges faced by professionals in the industry.

Product Information

Overview

Our Odessa Pumps and Power Service affiliated brands specialize in distributing, servicing and repairing progressive cavity pumps. Through our DNOW U.S. Process Solutions operating unit, we're dedicated to providing top-tier support to those in need of dependable fluid transfer solutions. Our PC pumps are crafted by top manufacturers with precision and innovation, perfect for tasks like fluid metering, managing thick materials or smooth solids handling. Not only are they high-performing, but they're also built for durability and sustainable operations. Enhance your systems with the best in fluid transfer technology.

Applications

Progressive cavity pumps are meticulously designed, considering various applications essential to industry professionals. Our inventory of PC pumps meets industry standards for performance and reliability in various applications, such as:

- Fluid Metering: ensuring precise fluid measurements for optimal processing

- High-Viscosity Liquids: handling thick fluids seamlessly

- Shear-Sensitive Liquids: gently maintaining fluid integrity

- Multi-Phase Fluid Transfer: efficiently managing varied fluid phases

- Automatic Custody Transfer (LACT/ACT): providing precision in measurements for accurate transfers

- Drilling Mud Transfer: facilitating uninterrupted transfer of drilling fluids

- Crude Oil Transfer: ensuring efficient crude oil movement even in tough conditions

Features

PC pumps deliver consistent performance, ensuring adaptability to diverse conditions and championing sustainable practices by encapsulating these principles in their core features:

- Rotary Positive Displacement Pump Design: perfect for solids handling and handling thick liquids

- Versatile Fluid Compatibility: handles everything from high GVF conditions to varying gas-to-liquid ratios

- Cutting-Edge Progressing Cavity Mechanism: directs fluid in an almost linear flow, preserving its quality

- Eco-Friendly Approach: prioritizes environmental safety alongside peak performance

- Cost-Effective: saves on installation, upkeep and operational costs compared to conventional multiphase fluid transfer systems

Specifications

| Materials of Construction | Cast iron, 316 stainless steel and a variety of rotor & stator materials |

|---|---|

| Flow Rate | Up to 63,000 bpd |

| Pressure Range | Up to 1,000 psig |

| Temperature Range | Up to 212° F |

A Selection of Supplier and Manufacturer Partnerships

FAQs

A PC pump is a type of pump that uses a single-threaded, external helix (rotor) turning within a double-threaded internal helix (stator). This design allows for a low shear pumping action ideal for multiphase fluid transfer without degrading or emulsifying the fluids.

Traditional fluid transfer requires separation equipment, which can be costly to install and maintain. PC pumps can transfer oil, gas and water through a single pipeline without degrading or emulsifying the fluids, making them an efficient solution.

Traditional pumps often struggle with rapidly fluctuating gas-to-liquid ratios, cannot handle suspended solids like sand and may have difficulty with varying API gravities. They can also emulsify fluids, complicating the separation process.

PC pumps can increase production, even from marginal wells, by significantly reducing wellhead pressures.

Yes, the Moyno Tri-Phaze System, for instance, can handle high gas volume fractions, high sand percentages, aromatics, changes in API gravity and H2S gas.

The spiral flow and low shear pumping action of PC pumps ensure that shear-sensitive liquids are transferred without degradation.