- Products & Services

- Process & Production Equipment

- Pressure Vessels

- Pressurized Bullet Tanks

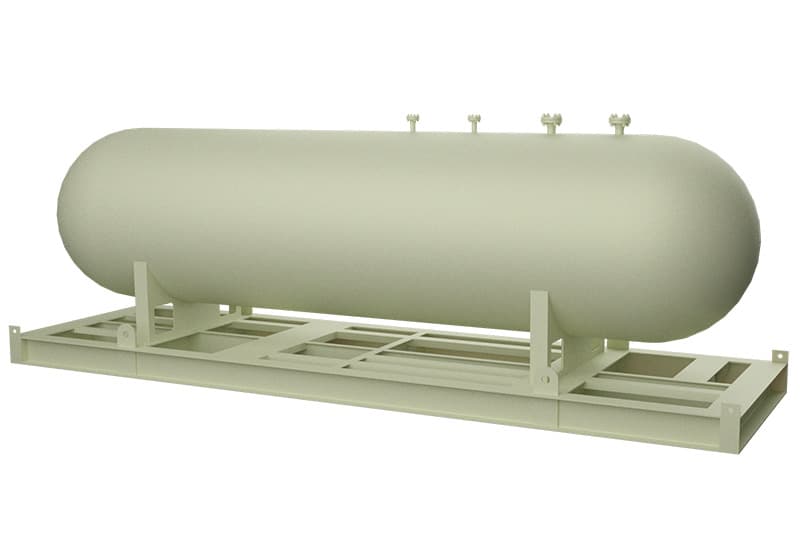

Pressurized Bullet Tanks

DNOW U.S. Process Solutions is an industry leader in the complete fabrication and design of bullet tanks and custom pressure vessels. From simple to complex and small to large, we will provide the most cost-effective solution to your vessel needs.

Product Information

Overview

Power Service is part of our DNOW U.S. Process Solutions operating unit. We pride ourselves on offering a wide range of pressurized bullet tanks engineered for the safe storage of liquefied petroleum gas (LPG) and natural gas liquids (NGLs). Our bullet tanks, a specialized type of pressure vessel, inherit all the general advantages of pressure vessels while also providing unique benefits due to their distinctive design.

Products Offered

We offer standard and custom tanks for safe storage of liquefied petroleum gas (LPG) and natural gas liquids (NGLs):

- Bullet tanks

- Custom vessels and internals

- Quick-opening swing bolt closures

- 2D and 3D CAD

- Specialized code vessel design

Features and Benefits

Pressure vessel-pressurized bullet tanks, often used in industries such as chemical, petrochemical, and oil and gas, offer several benefits:

- Efficient Storage of Gases and Liquids: Tanks are designed to store gases and liquids at high pressures, allowing for the efficient storage of large substances in a compact space. This is particularly useful for materials best stored under pressure, such as propane or natural gas.

- Cost-Effectiveness: Streamlined design translates into cost savings in manufacturing and maintenance.

- Ease of Transport and Installation: Their streamlined shape and robust construction make them suitable for transport. This mobility is essential for industries that require the movement of large volumes of pressurized substances.

- Versatile Applications: Bullet tanks can be designed for various applications and handle multiple substances, from volatile chemicals to cryogenic liquids. This flexibility makes them suitable for diverse industrial uses.

- Durability and Longevity: Constructed from high-strength materials, these tanks are designed to withstand extreme conditions and pressures, contributing to their longevity and reducing frequent replacements or maintenance.

Specifications

| Materials of Construction | Carbon steel, stainless & alloy steel |

|---|---|

| Dimensions | Vessels up to 12 ft. diameter, 100 ft. length, 8 in. wall thickness |

| Lifting Capabilities | Up to 100 tons |

| Non-Destructive Testing | Ultrasonic, hydrostatic, radiographic, dye penetrant inspection, positive material identification (PMI), hardness and others |

| Finishing | Surface prep, blasting, internal and external coating, painting |

| Engineering Support | Design, process simulation, finite element analysis (FEA) |